Product will be IQC, IPQC and FQC based on each product’s inspection standard. Quality data is inserted into QMS system for product quality analysis purpose.

Here are our quality equipment:

-

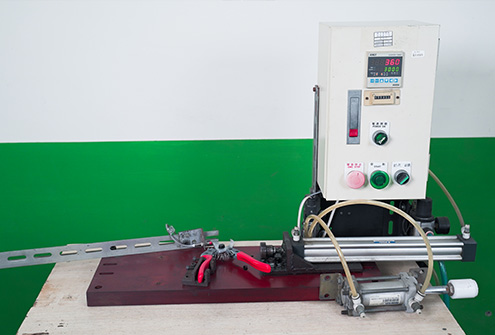

Automatic life testing machine

-

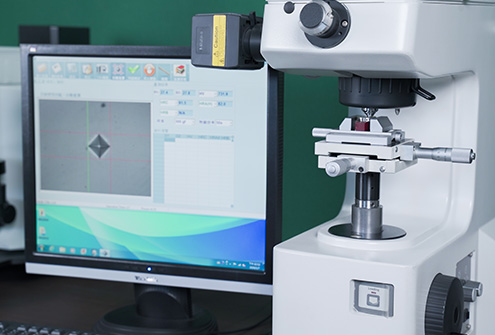

Metallographic hardness machine-for non-planar hardness testing

-

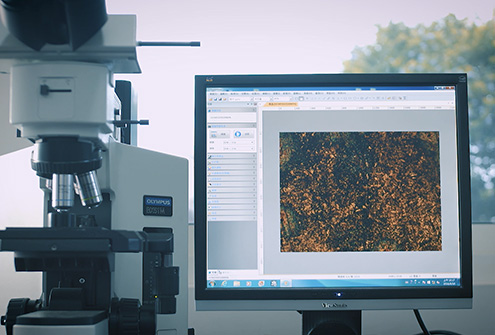

Metallographic Microscopy-Interpretation of Phase Changes in Metal Materials

-

Embedding-Metallographic Interpretation

-

Grinding and polishing machine

-

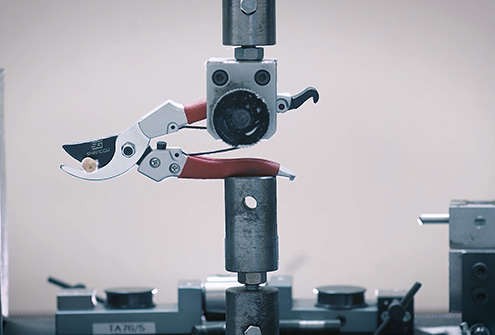

Cutter-metallographic interpretation cutting test piece

-

Color difference machine-product color interpretation

-

Multi light source color matching machine-product visual color difference judgment

-

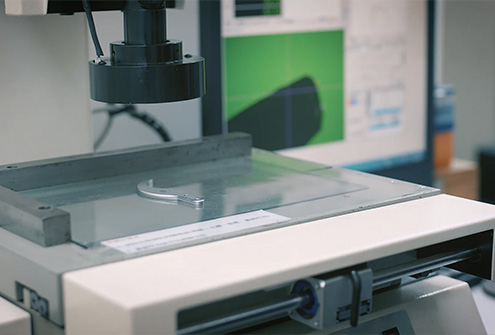

Two-dimensional image measuring machine-precision dimension measurement

-

The UK Indetec Rockwell hardness test machine

-

Weber Type B Hardness Tester-Hardness Interpretation of Aluminum Materials

-

Life testing machine-product empty shear and spring life test

-

Roughness Tester-Interpretation of Surface Roughness

-

Tensile Testing Machine-product bad force test and shear force test

-

Salt spray test machine-product rust resistance test

-

Barcode Detector-Barcode Interpretation

-

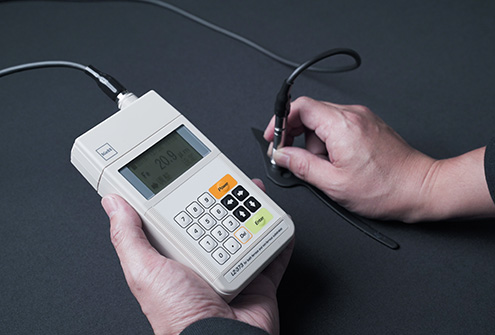

Film Thickness Machine-Part Surface Treatment Thickness Test

-

Push-pull force meter-big / small force and force test

-

Rubber hardness testing machine-rubber hardness test

No 76-30 Fuma St, Changhua City, Changhua County, Taiwan R.O.C 50084

No 76-30 Fuma St, Changhua City, Changhua County, Taiwan R.O.C 50084